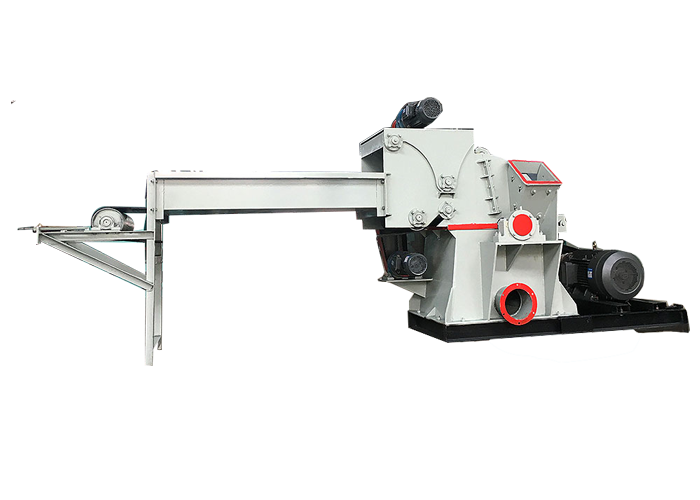

The fir skin crusher can also be used for the production of raw materials of particleboard, sawdust board, density board and paper mill. It covers a small area, has reasonable and compact structural layout, and is also suitable for mobile operation. It has crushing effect on poplar, bamboo, thatch, corn stalk, sorghum stalk, corn cob, pine, miscellaneous wood, waste wood, miscellaneous wood, raw bamboo and herbal straw.

After the fir skin crusher enters the crushing chamber and the crushed materials enter the machine body, the materials are roughly crushed by friction and shear during the mutual rotation of the rotating crushing disc and side tooth plate, and then enter the main surface of the crushing chamber for crushing and screening. After passing the required screening, they are discharged from the bottom. If they fail to meet the requirements, they continue to be crushed.

The fir skin crusher has crushing effect in the movement of the main surface of the crushing chamber. The materials can be crushed not only by the self shearing and self friction between the main surface of the material and the cutter board, between the main tooth plates, and between the materials. In order to prevent the vortex circulation caused by ultra-fine and slight materials in the crushing chamber, a fine powder removal chamber recovery cloth bag is set in the tangent direction of the crushing chamber.

The materials crushed by the fir veneer crusher are discharged and collected through the screen strip gap controlling the fineness below. The crushing of wood leftover materials is mainly to crush small wood boards, wood blocks, leftover materials, shavings, bamboo, multilayer boards, waste wood, twigs, branches, wood chips, leaves, bark, edge bark, etc., and processed into powder, sawdust, wood bran and wood chips. The thickness can be adjusted by screen, which is used in paper mill, furniture factory, density board, biomass particle factory, medium fiber board factory, etc.