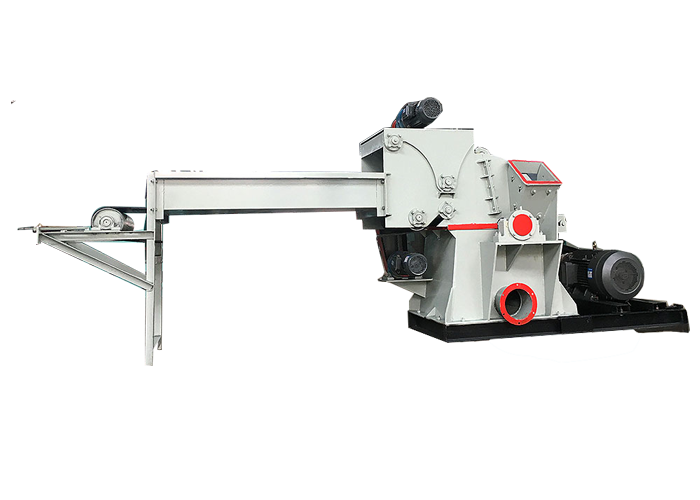

Application Areas:

The crusher can crush wood, trunk, branches, stalks, bamboo poles, wood blocks, twigs, leaves, bark, bamboo branches, bamboo leaves, feed, chemical raw materials and other materials into sawdust or sawdust, and the materials after crushing are widely used in sawdust.