1. If the rivet head of the impeller is worn, the worn rivet head can be returned to the original normal state by pressing the impeller body and the hub and surfacing with electric welding.

2. In the case that fatigue cracks are easy to occur at the rivet hole, the whole unused new welding rod can be used to repair the cracks, but it should be carried out symmetrically with the impeller axis as the center. Leave the remaining welding rod at the crack for repair welding, and then use a new welding rod to repair the relatively symmetrical rivet hole cracks. The remaining welding rod after welding is as long as the remaining welding rod during symmetrical rivet repair, To ensure that the weight of the weld repair is equal. If there is no crack at the symmetrical rivet hole, the welding rod shall also be welded here to offset the newly repaired welding weight at the crack of the symmetrical rivet hole. The crack can be repaired by welding according to this symmetrical weighting method.

3. Carry out a simple dynamic balance test on the impeller, and the method is also very simple. After supporting the impeller, move it by hand to rotate it gently. If it cannot reach the balance, it will stop at the lowest point and swing left and right. If there is a bias, spot welding can be carried out on the opposite impeller to increase the weight to make it balanced, or the welding mark of the bias impeller can be removed with an angle grinder to achieve balance, so that the fan can be repaired and work normally.

Note that during the repair of the fan, it is not allowed to spot weld randomly with electric welding, and leave the welding mark on the impeller, so as not to affect the balance of the fan impeller, fail to achieve the purpose of repair, and cause greater losses.

- Prev: 没有了!

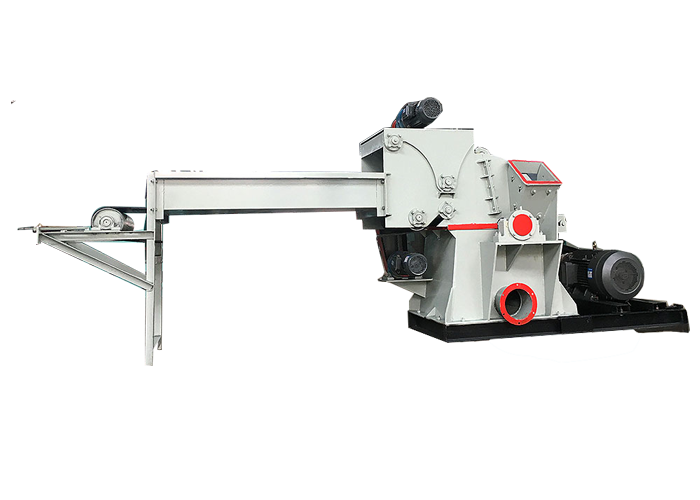

- Next: Precautions for branch crusher