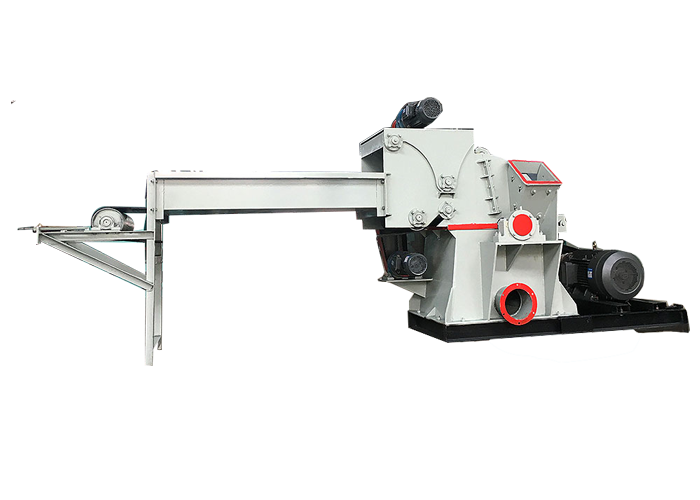

The crushing principle of the wood crusher is that the materials enter the warehouse and are crushed by the impact of the high-speed rotating hammer head. The crushed materials obtain kinetic energy from the hammer head of the hammer crusher and rush to the baffle and screen strip in the frame at high speed. At the same time, the materials collide with each other and are crushed for many times. The materials smaller than the gap between the screen strips are discharged from the gap, and some larger materials, On the screen strip, it is again impacted, ground and extruded by the hammer head, and the material is extruded from the gap by the hammer head of the hammer breaker. So as to obtain the product with the required granularity.

Wood pulverizer is a new type of ultra-fine wood pulverizing equipment newly developed by adopting high-tech advanced technology at home and abroad. It integrates the crushing principles of various traditional wood pulverizers at home and abroad, A high-efficiency and energy-saving wood pulverizer integrating three pulverizing principles has been successfully developed from a traditional wood pulverizer with pulverizing principle and a variety of pulverizing principles at home and abroad. The machine is equipped with a fineness analyzer. It is a new pulverizing equipment specializing in special difficult pulverization of light materials, fiber materials, brittle materials, ductile materials and so on. The feeding port of the machine adopts self-priming feeding to ensure safe production forever, replacing the shortcomings of direct feeding of the traditional crusher, careless input of metal blocks and serious damage to the wood flour machine. The machine has fine manufacture and high processing technology. It adopts a double-layer body. Tap water is injected into the body to cool the water. A new material is loaded to play the functions of sound insulation and heat dissipation. Therefore, the machine has low noise and no vibration in production and use.

It has beautiful appearance, firmness and durability, high output, and the efficiency is more than 50% higher than that of the traditional wood flour machine. It is an ideal flour making equipment that can not be replaced by any crushing equipment.

The debris crushed by the wood crusher is the main raw material used in the manufacture of synthetic plates. It is also the demand for building materials. It is also the raw material for the production of organic fertilizer and new combustion energy. In this way, it can not only protect the environment, but also save the production cost, which makes these waste wood give full play to their effective value, so as to provide high-tech production guarantee for the waste wood recycling industry and contribute to the cause of environmental protection.