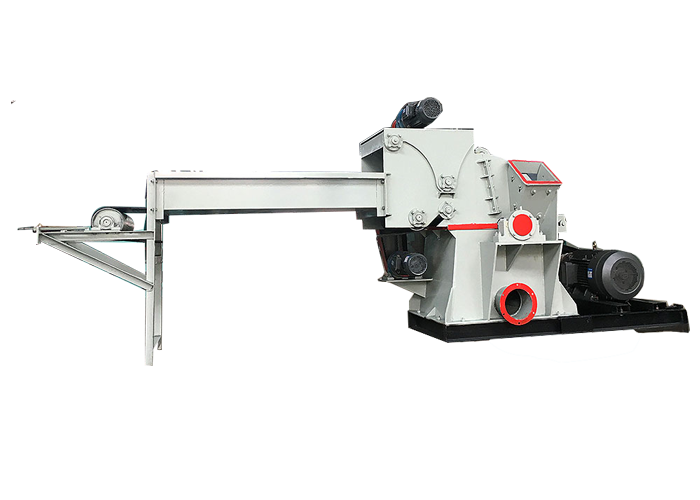

As we all know, there are many places in daily life will use the wood crusher, it can not only crush waste wood, but also directly crush branches and trunks, as long as it is wood processing enterprises can be used. But in the production will produce some wood dust, which makes the production environment become worse, many parts of the wood crusher need to be lubricated for a long time will be contaminated with wood chips, resulting in increased friction, serious machine wear and other problems, in addition to crushing different wood, some of the harder wood will also cause some wear to the internal blade, These require the daily maintenance of the wood crusher.

After a period of use, it is necessary to check the bearing part of the wood crusher, and the manufacturer has a protective cover on the bearing, in order to prevent the wood dust from falling, and also to protect the operator. But sometimes the protective cover will be attached to the bearing because the screw is loose, and the bearing friction wear, this is the need for special attention, the operator finds the situation to immediately tighten the screw, and replace the lubricating oil of the bearing to restore the smooth running of the bearing.

There are two kinds of wear-resistant lining plates installed in thea crushing room, one is to reduce the noise when crushing, and the other is to protect the crushing outdoor wall to avoid being broken by high-speed moving wood blocks for a long time. The liner needs to be checked regularly, generally half a year, and it should be replaced immediately if it is damaged. Grinding blade is also one of the accessories that wear relatively fast, in the case of continuous work for three months to six months, you need to check the blade, otherwise it will cause the size of the crushed wood is uneven, the machine is seriously worn, the bearing displacement and other situations, the loss will be the largest.

In addition to the above need to pay special attention to the situation, every day after the shutdown, try to arrange people to clean the wood chips above the wood crusher and the surrounding ground, to avoid accumulation of too much impact on the stability of the machine, but also reduce the risk of fire. Although the maintenance measures of the machine are cumbersome, some necessary maintenance is still to be done, which can maximize the efficiency of crushing wood and extend the service life of the wood crusher.