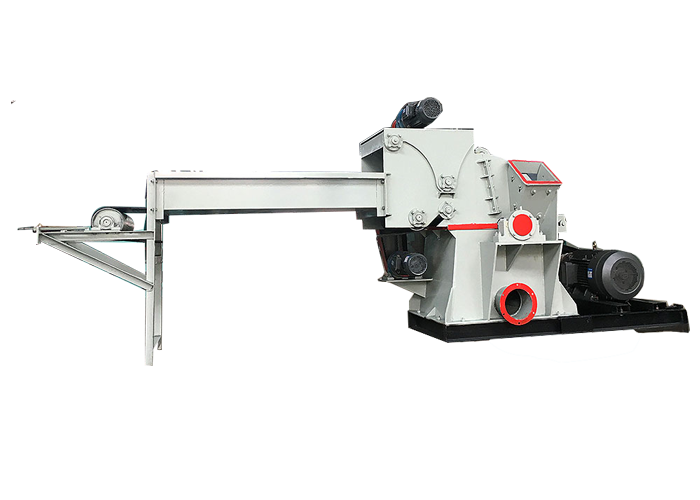

In addition to selecting the right equipment, installation and daily use and maintenance are also very important for customers to buy mechanical equipment, which is not only related to normal use, finished product qualification rate and output, but also related to the service life of the equipment. As a manufacturer specializing in the production of various crushing equipment, we have many years of strength and experience in design, production, installation and maintenance. According to the situation of the equipment, the following precautions are summarized:

1. First of all, please cooperate with the professional installation staff assigned by the company to prepare the basic work of site and foundation construction;

2. When using electricity as power, professional personnel should be found to make a reasonable layout of the line. Power lines and facilities shall be standardized and tidy, and shall not be installed or used without permission;

3. After the machine enters the site, the installation personnel shall conduct static inspection on the unit repeatedly and systematically, and conduct dynamic no-load test run for 3-5 minutes after confirming that there is no abnormality, and then it can be officially put into operation.

4. During operation, carefully check the processed materials and remove hard objects such as nails, stones and iron wires to avoid personal injury and machine damage.

5. Operators are strictly forbidden to wear gloves for operation. When feeding materials, they should stand on the side of the wood crusher to prevent rebound sundries from hurting their faces. Do not hold long stalk crops too tightly to prevent accidents.

6. During operation, no one is allowed to stand near the feed inlet of the machine and the turning point of the machine blade hammer. Pay close attention to the working condition of the wood crusher. If vibration, abnormal noise, excessive temperature of bearings and parts or outward spraying are found, stop the machine immediately for inspection, and continue to work after troubleshooting.

7. In case of blockage and overload, stop the machine immediately. It is strictly prohibited to forcibly feed with a wooden stick or hand, so as not to hurt the arm and damage the machine. After the completion of each shift, the unit shall be inspected and maintained to ensure that the operating unit is in good condition.

8. After the wood crusher is put into operation for about 10 days, open the cover, check the rotor, hammer and other operating parts, tighten the connecting bolts, and check whether the bearings are well lubricated. In case of clamping stagnation and collision, it shall be eliminated in time.