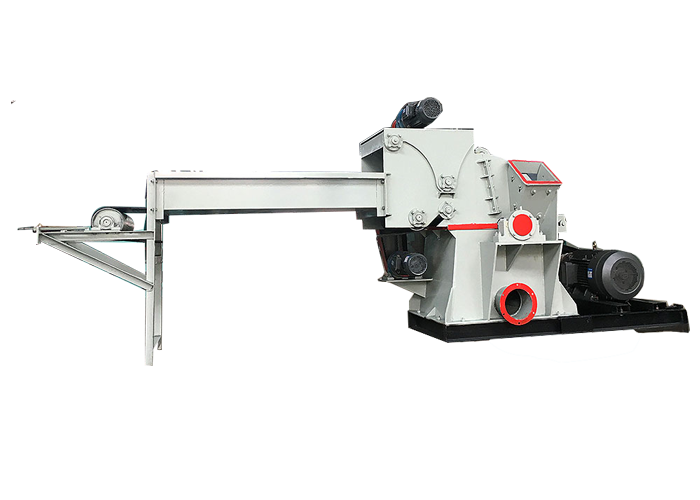

1. Crushing rate of tree crusher

That is, the percentage of crushed materials that meet the specified size after treatment in the total quantity of crushed materials.

2. Minimum thinning size of tree crusher

That is, the minimum size of the treated crushed material.

For example: if it is used for forestry pestilence wood crushing, the national standard requires that the pine wood should be treated to a thickness of less than 0.6cm. When purchasing the tree crusher, we need to pay attention to its minimum refinement size. Zhongneng is equipped with a tree chipper crusher qtg300, which is designed for the treatment of forestry waste and forestry diseased wood. The fineness of the broken powder can reach 3mm, which fully meets the national requirements for the treatment of diseased wood.

3. Diameter of crushed material of tree crusher

That is, the maximum diameter of the branch that can be treated.

For example, each kind of tree crusher has provisions on the maximum diameter of materials to be processed. For users, it is not the better to choose a tree crusher with a larger processing diameter. The diameter of forestry waste collected by enterprise a is generally less than 20cm, so the most appropriate one is about 20cm. For example, selecting a tree crusher with a diameter of 30cm will not only cost a lot, but also waste resources.

4. Treatment capacity of tree crusher

That is, the amount of crushed material processed per hour.

For example: the crushing rate of a crusher is very high, but it is less than 0.5m per hour ³ The processing capacity still can not meet the actual requirements of most enterprises.

5. Number of tree crushers

That is, determine the number of tree crushers to be purchased according to their own needs.

For example: under the condition of more forest waste, a single forest crusher can not meet the actual demand or the cost is very high, so it is necessary to calculate the total volume to be crushed in advance, so as to determine the number of designed crushers. For example, the total volume of waste wood produced by ecological park a every day is 50m ³, The processing capacity of a single crusher is 10 m ³/ d. Then 5 sets of equipment need to be installed to meet the requirements.

6. After sales service issues

Service life, renewal and maintenance cycle and cost of crusher.

For example: some parts of the tree crusher have a service life. Detailed consultation is required before purchase, and the after-sales maintenance method, price, cycle and cost of main parts also need to be understood.