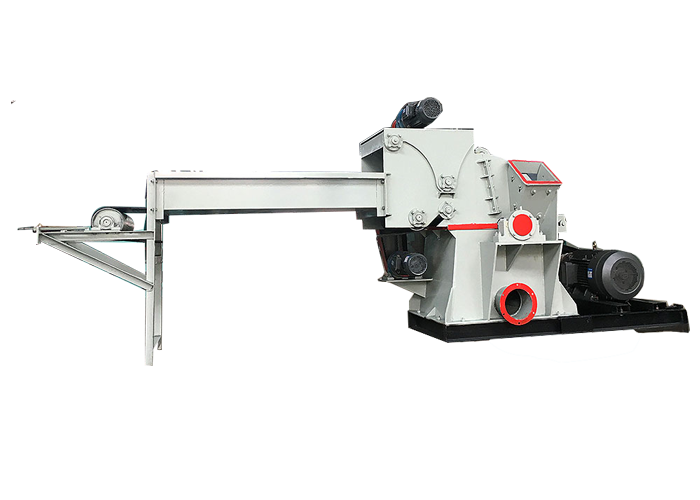

1. Check the following items of the unit before work:

I. check whether electrical equipment components (including motor wiring) have leakage, and ensure safety.

II whether the bolts of all parts of the unit are fastened, especially the rotor bearing seat of the crusher and the lower body support seat shall be firmly connected without looseness.

III. whether the hammer piece is in good condition, whether the aperture of the screen piece is appropriate and whether there is damage. The damper is usually fixed in the half open or full open position.

Ⅳ the moisture content of the materials to be processed shall be controlled below 15%. When feeding, shake the grass with a fork and then feed it, so as to prevent the damage of machine parts caused by iron blocks and stones sandwiched in the materials.

V. regularly inspect the parts of the crusher. If the lubricating grease in the bearing hardens and deteriorates, clean it with clean kerosene or diesel oil and inject new grease (No. 3 or No. 4 calcium base grease).

2. When working, start the vehicle for 1-2 minutes, check whether the direction of the crusher is correct and whether the sound is normal. It can work only if there is no abnormality.

3. When working, the operators should tighten their sleeves, and the female comrades should wear work hats and stand on both sides of the machine, not in front of the feed inlet.

4. When working, it is not allowed to put your hand into the crushing room for feeding, and it is not allowed to use iron rod for filling. The feeding shall be uniform and appropriate.

5. During the operation of the machine, the operator shall not leave the unit, nor dismantle and look inside the crushing chamber during the work. The tools shall not be placed on the machine or material pile. If the machine is found to be in abnormal sound, discharge blockage, bearing or motor overheating, it shall be stopped immediately and restarted after troubleshooting.

6. Do not stop the machine immediately after filling the materials, but idle for another 2-3 minutes to remove the residues in the machine.

7. The machine shall be started under no-load. If there is any material stored, it shall be emptied before starting.

8. The cotter pin on the hammer pin shaft shall be checked frequently. If there is excessive wear or cracking and peeling, it shall be replaced immediately.

9. After working every day, cut off the power supply and clean the site.