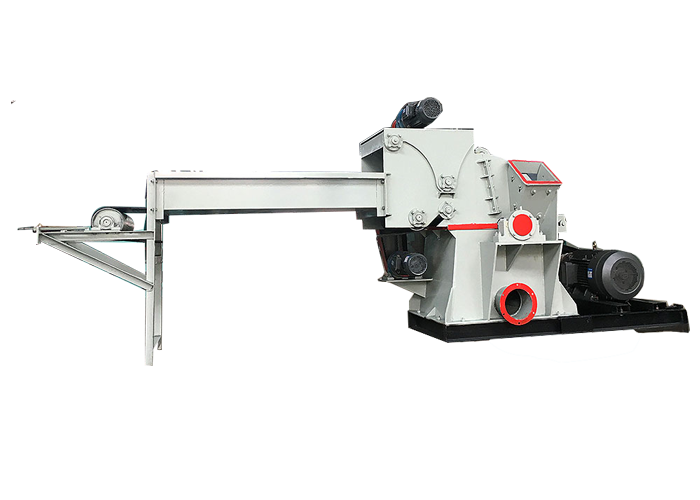

1. The vibration crusher generally adopts the motor to directly connect the crushing device, which is simple and easy to maintain. However, if the two cannot be well connected in the assembly process, it will cause the overall vibration of the crusher.

(1) The motor rotor is not concentric with the crusher rotor. The position of the motor can be moved left and right, or a pad can be added under the foot of the motor to adjust the concentricity of the two rotors.

(2) The rotor of the pulverizer is not concentric. The reason is that the two bearing surfaces of the palm rotor shaft are not in the same plane. Copper sheet can be padded on the bottom surface of the supporting bearing seat, or an adjustable wedge iron can be added at the bottom of the bearing to ensure that the two shaft heads are concentric.

(3) The vibration of the crushing chamber is large. The reason for the straw granulator is that the connection between the coupling and the rotor is not concentric or the quality of the flat hammer inside the rotor is uneven. Corresponding methods can be adopted according to different types of couplings to complete the connection between the coupling and the motor: when the quality of the hammer pieces is uneven, each group of hammer pieces must be re selected to make the symmetrical hammer pieces, so that the error of the symmetrical hammer pieces is less than 5g.

(4) The original balance is broken. After the motor is repaired, a dynamic balance test must be carried out to ensure the overall matching balance.

(5) The hammer blade is broken or crushed, and there are hard sundries in the room. All of these will cause the unbalance of rotor rotation and cause the vibration of the whole machine. Therefore, it is necessary to check regularly for the hammer piece with serious wear. Replace symmetrically when replacing; In case of abnormal sound during the operation of the crusher, stop the machine immediately for inspection, find out the cause and deal with it in time. The foundation bolts of the crusher system are loose or the foundation is not firm. During installation or maintenance, the foundation bolts shall be tightened evenly. A damping device shall be installed between the foundation and the crusher to reduce vibration.

(6) The connection between the pulverizer system and other equipment is inconsistent. For example, improper connection of feed pipe and discharge pipe will cause vibration and noise. Therefore, these connecting parts should not adopt hard connection, and it is best to adopt soft connection.