During the use of the wood chip machine, many parts will be worn or deformed due to severe grinding, impact, etc. Some customers said that when the sawdust fuselage is deformed, the manufacturer made it clear at the time of purchase that it is durable steel, which used a period of time to distort the sawdust machine bracket, the bearing interior also began to deform, the situation reflected by the customer is closely related to the quality of the sawdust machine itself, which also has a lot to do with the user's use method and skills, so how can we avoid this situation?

The material does not move back and forth in the drum, that is, the processed material cannot be repeatedly crushed in the silo, and the blower can extract the material in the drum quickly. Therefore, the storage of the material in the cylinder is too low, resulting in the material is difficult to contact the processing area, so that the material can not be crushed normally. Therefore, in the processing process, some wood chip machine manufacturers have a responsibility to the customer, at this point can be seen, it is recommended that individual customers do not put too much material, equipment in the testing machine or just run stage can not be too little. There are also some wood crusher equipment feed port tilt, the wood chip machine is mainly in the installation method, the inclination need to maintain a certain inclination Angle, not random installation, otherwise too far from the motor will cause low utilization of drum space, a large amount of heat loss, wood processing and operation bring unnecessary obstacles.

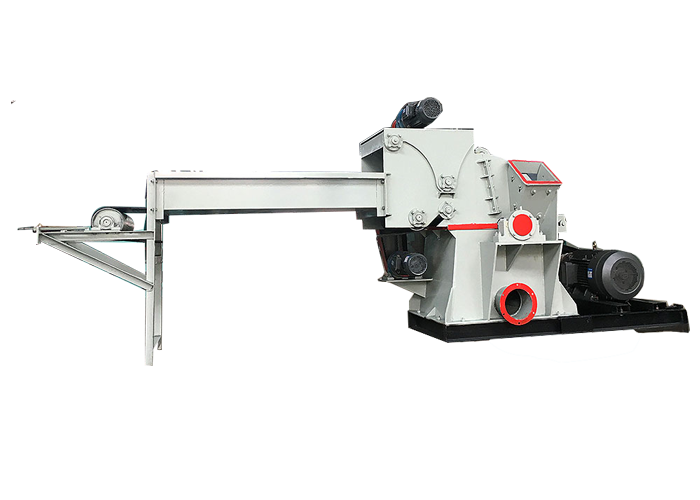

These devices look no different, but why are the finished products so different? Wood chip machine is an ideal production of wood powder woodworking machinery and equipment, wood, branches and other raw materials can be processed into wood chips and sawdust at the same time, with less investment, low energy consumption, high productivity, good economic benefits, easy to use and maintenance. The wood chip machine is convenient to operate, easy to change the tool, the optimized design of the tool holder, the claw knife can disperse the strength, maximize the shear force of each knife, suitable for crushing thick material, hard material block, material, etc., effectively maximize the cutting force of the tool, reduce the wear of the tool. Using electronic control design, the material head adopts a double-layer structure, filled with sound insulation material, which greatly improves the level, saves power and durability